Palm oil’s supply chain goes through a long and intricate path from the point of harvest to refinery and consumer’s plate. Generally speaking, the value chain entails how it travels from one stakeholder to another involving farmers, mill and refinery operators, suppliers, manufacturers, exporters, importers, wholesalers, retailers and consumers. The complexity is beyond our comprehension.

Emphasizing the traceability of palm oil’s supply chain is becoming a mainstream practice for major players, including Sime Darby Plantation. Being the world’s largest producer of certified sustainable palm oil at the same time, the company is at the forefront of manifesting the transparency of its supply chain to the whole world.

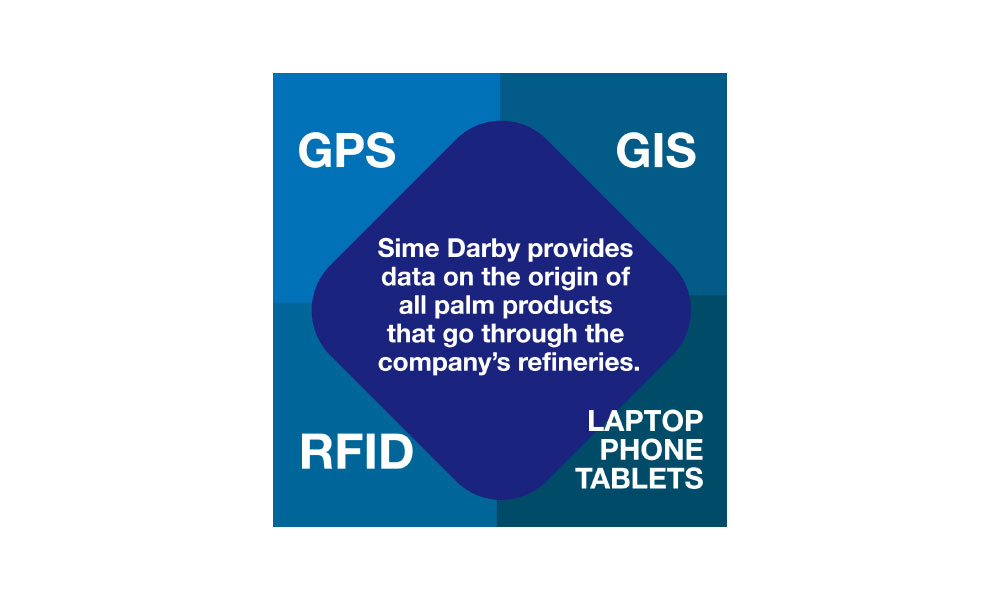

The Open Palm online dashboard by Sime Darby Plantation is a prime example. It provides consumers with key data on the origin of all palm products that go through the company’s refineries - be it from its various oil palm mills, right down to its plantations, or the third party plantations. Full access to the traceability report will, however, only be made available to its key clients in order to protect the confidential nature of commercial information contained, which may include data on products and purchasing patterns.

So what makes this possible? The answer lies in utilizing Big Data Analytics driven digital technology with the help of purpose-built software and hardware such as data analysis by Geographic Information System (GIS), Global Positioning System (GPS) and Radio-Frequency Identification (RFID) tagging, together with the use of handheld digital devices including laptops, tablets and smartphones. The use of smart technology ensures the information produced is accurate and reliable.

The location-based data gathering system is able to inform consumers about palm oil’s full journey from plantation to supermarket shelf (end-to-end visibility) by scanning the designated Quick Response (QR) code on product label, for instance. The information about how it travels through the supply chain tells consumers whether the retailed product was sourced and produced sustainably – a key monitoring yardstick in sustainable palm oil production that attests to the commitment pledged by major producers.

For consumers making a purchase, the key information includes where, when and how the product was harvested, and how it was produced, plus other supply chain paths that it went through. Better still, they get to know and understand every part of the supply chain.

The digital traceability of palm oil supply chain is thus far the most transparent, reliable and practical method to uphold ‘supply chain accountability’ by upstream, midstream or downstream stakeholders. As industry players raise their standards, it is about a mindset shift that augurs well for the sustainability of the palm oil industry with improved processes and procedures, governance and performance.

Industry analysts believe that such innovative practices are transforming the palm oil industry into a more sustainable, productive and resilient state, particularly with the increasing participation by smallholders.