Whether you're managing a cold storage facility, running a supermarket chain, or engineering HVAC systems, the question is no longer if you should switch refrigerants, but which one best suits your operation. With climate regulations tightening, energy costs rising, and technology advancing at full speed, choosing the right refrigerant today means setting the foundation for a more sustainable and competitive tomorrow.

Technology Day 2025, hosted by NRS Process Systems Sdn Bhd, brought together leading minds in cooling and freezing technologies to explore what’s next in sustainable refrigeration. Since 1988, NRS has been delivering tailored cooling and freezing solutions for industrial and warehouse applications, meeting the most demanding requirements with precision.

The event welcomed manufacturers, engineers, and business leaders looking to future-proof operations in an evolving landscape. The full-day programme featured 11 speakers from top corporations, academic institutions, and government agencies.

Why Natural Refrigerants Are the Future

For decades, synthetic refrigerants like R-134a, R-404A, and R-410A have been widely used in commercial and industrial refrigeration. However, governments worldwide are phasing them out due to their high GWP and environmental impact for alternatives such as natural or low-GWP refrigerants.

During his opening remarks, Chew Soon Jin, CEO and Technical Director of NRS Process Systems, explained the need to transition away from synthetic refrigerants, including those with harmful chemicals.

“Natural refrigerants like ammonia, CO₂, and propane are not only safer for the environment, but they’re often more energy-efficient, cutting both emissions and costs. While the transition is challenging, it's necessary. At NRS Process Systems, our strength lies in customising refrigeration systems that prioritise performance, energy efficiency, and safety,” he said.

Cooling technologies are essential to our everyday lives, but the common types of refrigerants include synthetic compounds like hydrofluorocarbons (HFCs), are major contributors to climate change. Ryan Ooi Chean Weai from the Department of Environment shared that Malaysia has already stopped importing CFCs and HCFCs and is now regulating HFC imports, offering training programmes, and helping industries shift to safer, greener alternatives. Without action, HFC emissions could quadruple by 2045.

But with Malaysia’s commitment under the Kigali Amendment, the country aims to cut these emissions by 80%—proving that environmental responsibility can go hand in hand with sustainable development and innovation.

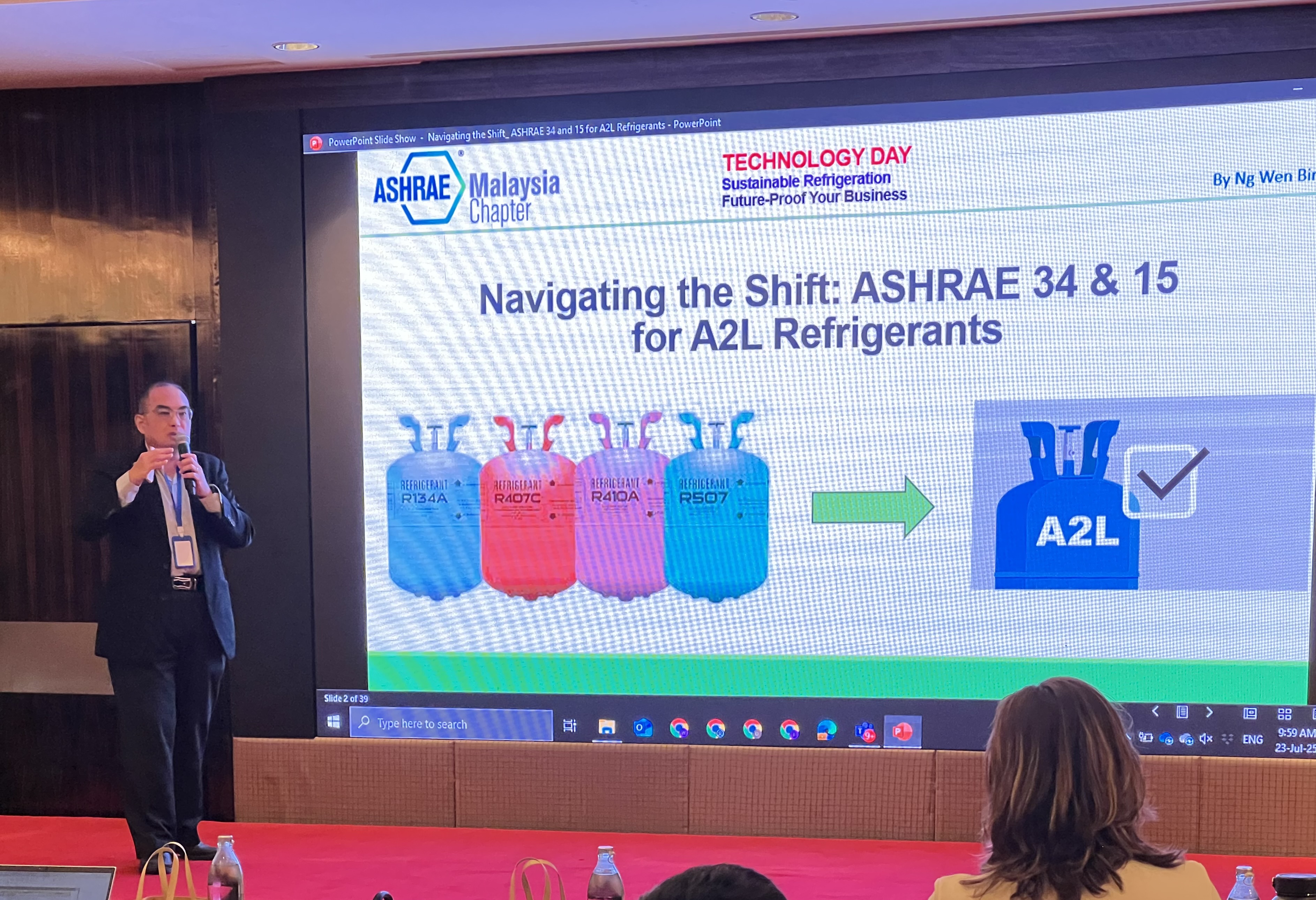

“The Kigali Agreement is a global deal to phase down harmful HFCs used in cooling systems. It helps fight climate change and opens doors for trade in eco-friendly tech. Without it, countries can’t trade, buy, or sell HFC-related products with those that signed the deal, risking market isolation and outdated tech,” said Ng Wen Bin, Refrigeration Chair, ASHRAE Malaysia Chapter.

He also shared the core principles of ASHRAE Standard 15, which focuses on refrigeration safety and environmental responsibility. These include keeping refrigerants securely contained within their systems and, in the event of a potential release, minimising harm to people, either by limiting refrigerant quantities in direct systems or by housing larger systems within dedicated machinery rooms.

Smarter, Greener Cooling with AI & IoT

In his session titled "Intelligent Refrigeration – How AI & IoT Can Drive Sustainable Cooling Solutions," Nguyen Hong Quang, Regional Sales Director of Guntner Asia-Pacific Pte Ltd, explored how future cooling systems can be designed with built-in sustainability features. According to him, smart systems can deliver:

25% energy savings through optimised cooling cycles

15% reduction in carbon emissions

20% cut in maintenance costs via predictive servicing

99.9% compliance with food safety temperature standards

CO₂ vs HFC Systems: What You Need to Know

Lee Heng Seng, Senior Manager of Application Engineering for NEA & SEA at Copeland, outlined the top 10 technical differences between CO₂ and HFC systems—key knowledge for those planning to transition to natural refrigerants. Among the major contrasts are the use of booster design in CO₂ systems, gas coolers instead of traditional condensers, and significantly higher discharge pressures.

CO₂ also has a low critical point, requiring specialised high-pressure and bypass valves, as well as a flash tank for liquid-vapour separation and dedicated oil management systems. Additionally, CO₂ systems rely more heavily on precise electronic controls and must account for high standstill pressure due to CO₂’s high triple point, necessitating robust pressure relief solutions.

As the industry embraces cleaner, more efficient refrigeration methods, innovation and collaboration are key. Technology Day 2025 doesn’t just highlight the challenges ahead—it showcases the opportunities. From advanced safety standards and government support to smart technologies that boost efficiency, the shift toward natural refrigerants is already underway.

By partnering with a trusted refrigeration specialist, you can ensure a seamless shift and optimise your system from day one. Don’t wait until regulations force you to change—start planning your transition today! Visit https://nrs.com.my/ for more info.

#technologyday #sustainablerefrigerant